|

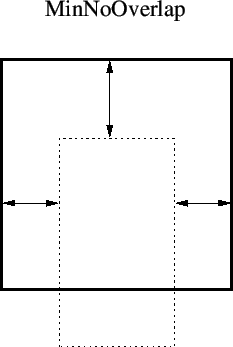

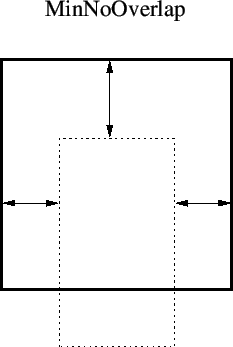

For the parts of each edge of the source that are not coincident or overlapping with source-compatible figures or with target figures which extend into the interior of the source figure, a rectangle extending normally from the edge into the source figure a distance given by the dimension is constructed. The test fails if the constructed rectangle has nonzero intersection area with target figures. Figure 15.13 illustrates the test performed under this keyword, for no Region and an expression consisting of a single layer.

|