Next: Device Templates

Up: Extraction System: Setup and

Previous: Extraction System: Setup and

Contents

Index

Device Blocks

Physical characteristics of devices which are candidates for

extraction are specified in device blocks in the technology file. The

device blocks are located in the technology file after the physical

layer definitions. These specifications enable automated extraction

of circuits from physical layouts.

Devices are specified in the technology file through a block of lines

keyed by the word ``Device'' and ending with ``End''. An

example is below:

Device

Name res

Prefix R_

Body R2

Contact + M2 I1B&R2

Contact - M2 I1B&R2 ...

Permute + -

Depth 1

Merge S

Measure Resistance Resistance

LVS Resistance

Spice %n% %c%+ %c%- %ms3%Resistance

Cmput Resistor %e%, resistance = %ms3%Resistance

Value %m%Resistance

End

There can be no text following Device in that line. The block

must terminate with End.

The device block in the example specifies a resistor device:

- The resistor body consists of areas of layer R2.

- Contact is made to conductor M2 through a region of

I1B (which represents a physical via).

- The resistor can have arbitrarily many contacts (...

given in second Contact line). This will be decomposed

into a network of two-terminal resistors by the extraction system.

- The (two) terminals are interchangeable (Permute given).

- Parts of the resistor can be found in subcells (Depth of 1).

- Two-terminal resistors in series and in parallel will be merged

iteratively into simplified networks.

- The resistance of the structure will be measured and reported.

The keywords are described in detail below.

- Template template_name argument ...

This will access the device template with the given template_name. Text from the template will be inserted into the

current device block, after macro, variable, and argument

substitution. For argument substitution, forms like ``$(_N)'', with N being a positive integer, will be replaced

by the N'th argument, with any quote marks stripped. If an

argument contains white space or other strange characters, it should

be double-quoted.

The template can provide all of the keyword text for the current

device block, or additional keywords from the list below can be

provided to supplement the template. It may not be possible to

redefine an alredy defined keyword however.

- Name device_name

The device_name names the device, which should match a device

cell name. The name can be that of a parameterized cell, or a regular

device cell from the device library (device.lib) file, or a

device cell from some other source. This line is mandatory.

Two or more device blocks can use the same name if they have different

Prefix entries. This might be useful, for example, if there are

two resistor layers in a process. A device block would be needed to

describe resistors on each layer.

- Prefix prefix

This is a prefix that is prepended when formulating the name for the

device used in output. This is optional, as a prefix can also be

defined in the output formatting. The first letter of the prefix

should match the expectations of the SPICE simulator or other tools to

be used. If two or more device definition blocks have the same Name field, they must have different Prefix fields. Further,

each definition must have identical contact and bulk contact names,

and order, and identical permutable contact names.

- Body expression

The Body keyword specifies the ``core'' physical feature of the

device. The specification is a layer expression. Each individual

region where the expression is true defines a potential instance of

the device. This keyword is mandatory.

- Contact name layer expression [...]

For each contact of the device, there should be a Contact line.

The first token following Contact is a name for the contact,

which should match the corresponding name used in the node property of

the device in the device library file. The second token is a layer

name of a conductor layer which is used to contact the device. The

remainder is an expression which identifies the contact area. The

contact is identified as a region inside the device bounding box where

the expression is true. Multiple contacts using the same expression

can be given, and each will select a different region. The device

bounding box is the bounding box of the body area, after the Bloat operation (see below).

If the Contact line ends with ``...'' (three periods)

there can be more than one of that type of contact. Ordinarily, there

is a one-to-one correspondence between contacts specified and contacts

in the device instance. With the ellipses, device instances will

include as many of that type of contact as can be found. Thus, such

devices no longer have a fixed number of contacts. The ellipses can

not appear in the first Contact line, but may appear in

the second and/or subsequent Contact lines.

The ellipses feature presently supports multi-contact resistors. A

multi-contact resistor is replaced internally by a network of

two-terminal resistors, which are used in the netlist output. To

enable multi-contact resistor support, the second contact

specification in the resistor device block should end with ``...'', for example

Contact + M2 I1B&R2

Contact - M2 I1B&R2 ...

This specifies that as many of the second type of contact as can be

found will be extracted. Without the ``...'' only two contacts

would be extracted. The ellipses can not occur on the first contact

line, but may occur on other lines, and may occur more than once,

though no standard devices use this feature presently. In general,

this implements device extraction with arbitrary numbers of certain

contacts.

Internally, a conductivity matrix is computed from the body and

contact geometry, and this is used to compute the effective values of

the two-terminal resistors that are used to implement the

multi-contact resistor. Resistors that would have very high values

(larger than 100 times the smallest value) are not added, so that

linear multi-contact resistors decompose as one would expect.

The decomposition occurs before the serial/parallel merging, so that

the components of the decomposition are candidates for merging, if

merging is enabled (see the Merge keyword below).

- BulkContact tname level [name |

bloat layername expression]

This is a special form of a contact specification that applies to well

and substrate connections, which may be treated differently than other

contacts. The tname is the contact name. This is followed by

an integer level which determines how the contact is handled

during extraction. Possible level values are as follows. The

remaining entries in the line depend on the level. There can be

at most one BulkContact line in the device description.

- 0

Check in cell during device extraction. This requires that a bloat value, layername, and expression follow the level

number. The body bounding box is (logically) bloated by the bloat value given (in microns). Within the bloated area, a region

where the expression (a layer expression) is dark, that is

connected to the conductor layername must exist. If there are

multiple areas, the one closest to the bounding box center is taken as

the contact area. If there is no such area, the device will not be

recognized. The search hierarchy depth for the contact is to all

levels.

- 1

Ignore this in extraction. The level value must be followed by a name, which is the name of a global net. The contact will be

assumed to connect to that global net. Use this mode only if it is

absolutely certain that physically the bulk contact is connected

properly, as this mode does no checking. Use this at your own risk.

- 2

Check deferred. This requires that a bloat value, layername, and expression follow the level number. During

extraction and association, if the contact can't be resolved within

its containing cell, level=2 contacts are ignored as for level=1.

During LVS, a special ``stamping'' test is run over the complete

hierarchy, and any errors found are reported with the top-level cell.

This test searches for unresloved level=2 contacts in the

hierarchy. It will try and resolve the contact at the top level (thus

taking account of all geometry in the hierarchy). If unsuccessful,

the device location as reflected to the top level coordinates will be

listed in the stamping report, and LVS will not succeed.

- Bloat increment

This will expand the body bounding box by increment (in microns)

for the purpose of identifying contacts. For example, a MOS

transistor body is the intersection of CAA and CPG. The source and

drain contacts can be specified as the regions of the body bounding

box after a bloat that cover CAA but not CPG.

- ContactsOverlap

Ordinarily, device contact areas can not overlap. The extracted

contact areas are clipped against one another to enforce this. Giving

this keyword allows overlap, which is necessary for some vertical

device structures.

- Permute name1 name2

The names are the names of contacts that can be permuted to enable

association when comparing to a schematic. This applies to devices

such as resistors, and to the source and drain of MOS devices, or to

any device containing a contact pair that are geometrically identical

to the extractor. There must be exactly two names following

``Permute'', and only one Permute line is allowed.

- Depth depth

The depth is the hierarchy depth extracted for the device,

default is 0, meaning all device structure should appear is the

current cell. The value can be an integer, or `a' to look at the full

hierarchy.

- Find [device_name][.prefix]

This will cause a device with the given name and prefix to be searched

for in the current device's bounding area, and added to an internal

list. Any number of Find directives can be applied. If two or

more directives look for the same name/prefix, they will return

different instances. Currently, this is used only for identifying

inductors in a mutual inductor device.

- Merge [arg]

This optional keyword specifies how to handle parallel and series

connected instances of the device for parameter extraction. There is

an optional argument. Merging implies that multiple devices are

combined internally and reported as single devices in netlists and

SPICE output. If both parallel and series merging are enabled, the

merging process is iterative, and will continue until no further

merging is possible.

If no Merge keyword appears in the device block, no merging is

done for that device. Only the first two characters of the arg

are tested, case insensitively, and any remaining characters are

ignored. Series merging will be enabled only for two-terminal devices

that have the Permute keyword applied, i.e., typically

resistors, capacitors, inductors.

| arg |

Merge |

|---|

| no arg |

parallel |

| "s" |

parallel and series |

| "ns" or "sn" |

series |

| unrecognized |

error |

Merging can also be controlled by the variables NoMergeParallel

and NoMergeSeries which are booleans which can be set with the

!set command. The variables suppress merging of the indicated

kind, parallel or series, for all devices.

Merging can also be suppressed on an individual device basis by

applying a NoMerge property to an object that is used in the

body of the device. This property can be added with the Property

Editor.

Merging can lead to confusion, particularly when users are

experimenting. Unless the aggregate has external connections, it is

likely to be merged down to a single device in ways which may be

surprising.

Example:

The Show computed parameters of selected device option of the

Enable Select command mode in the Show/Select Devices

panel from the Device Selection button in the Extract Menu

is useful for displaying the values of extracted devices, and shows

the effect of merging. When resistor networks are merged, Xic will

merge series resistors if there are no other connections at the common

node. Sometimes, this will lead to a configuration that is not

intended or desired, for example if the desired end terminal of the

network is connected to two resistors only, that node might be merged

away. Xic will merge devices arbitrarily if there is insufficient

information available to uniquely define how merging is to be done.

One way to prevent this from happening is to use temporary virtual

terminals:

- Switch to electrical mode.

- Enter the subct side menu command.

- Press Ctrl and click anywhere in the drawing window. A

terminal marker will appear. Dismiss the Terminal Edit pop-up,

and switch back to physical mode.

- Press the Setup button in the Extract Menu to obtain

the Extraction Setup panel. Press Edit Terminals in the

panel. A terminal mark should appear to the lower left of the

bounding box of the current cell.

- Move the terminal mark to the desired network end terminal

metal.

This node now has a (phony) terminal, so it won't be merged.

Don't forget to go back and delete the terminal when done.

The way the parameters are computed upon merging is determined by the

Measure keyword (see below). Series merging is applicable to

resistor, capacitor, and inductor-type devices.

| Measure Keyword |

Parallel Action |

Series Action |

|---|

| BodyArea |

Sum |

Sum |

|---|

| BodyPerim |

Sum |

Sum |

|---|

| BodyMinDimen |

Min1

|

Min |

|---|

| CArea |

Sum2

|

- |

|---|

| CPerim |

Sum2

|

- |

|---|

| CWidth |

- |

- |

|---|

| CNWidth |

- |

- |

|---|

| CBWidth |

Average |

Sum |

|---|

| CBNWidth |

Sum |

Average |

|---|

| Resistance |

Parallel Resistance |

Sum |

|---|

| Inductance |

Parallel Resistance |

Sum |

|---|

| Mutual_Inductance |

not implemented |

not implemented |

|---|

| Capacitance |

Sum |

Parallel Resistance |

|---|

Notes:

1) Although the minimum of the multiple sections is used, for MOS

devices each value is typically the same.

2) If devices of the same type share a contact, the contact

area and perimeter are divided equally between the devices.

The fields with `-' above are invalid, and return 0 if accessed.

The ``Merge M'' feature of earlier releases is no longer

supported. This would average the parameters of parallel-connected

MOS devices, and automatically add the ``M='' (multiplier)

parameter to the SPICE output line. Now, the merging behavior is as

described above, and no multiplier is automatically added to the SPICE

line. The Sections measurement keyword (below) can be used to

explicitly format the SPICE output to use the multiplier parameter, if

desired.

- Measure mname expression [precision]

The Measure keyword allows geometrical information to be

extracted from the device, which is listed with the Dump Phys

Netlist command in the Extract Menu and used in other

commands in the Extract menu.

- mname

A name for the parameter te be extracted. This is arbitrary but

should be unique for the device. This is the name by which the

particular measurement result is referenced.

- precision

The optional precision is a non-negative integer which applies

to comparing electrical and physical values in layout vs. schematic

(LVS) testing. The default is 2 if not given. If the value given is

n, then the two values must agree to a part in 10n

, e.g., to

within 1 percent for the default value of 2.

- expression

The expression consists of an expression in the format

recognized in scripts, where the variables are either the names from

previously defined Measure lines (in the current device block)

or the keywords below. The expression is evaluated during extraction

yielding the result of the measurement. The math functions are

available in the expression as are all of the math operators.

There can be arbitrarily many Measure lines.

Below is a list of the ``primitive'' measurement tokens which can

appear in the measurement expressions. In several cases, the token

consists of three fields, separated by `.'. The additional fields

supply modifiers to the primitive measurement indicated by the token

name (the first field).

The basic unit of length is one micron.

- Sections

This returns the number of components of the device, which will be

greater than one if the device is an aggregate of several series or

parallel-connected devices (Merge enabled).

- BodyArea

The area of the region where the Body expression is true.

- BodyPerim

The perimeter length where the Body expression is true.

- BodyMinDimen

This is a minimum dimension computed using the body geometry. There

are several ways that this can be computed, depending on other

keywords and the device type. The default algorithm first decomposes

the body shape into a trapezoid list. the mid-height width and height

of each trapezoid is added to a histogram, weighted by the other

value. For example, width=2, height=3 would add to the histogram 2

with weight 3, and 3 with weight 2. When done, the value with the

largest weight will be taken as the BodyMinDimen. If a tie, the

smaller value is used. This is effective on structures where a ``line

width'' is an applicable concept.

However, if the SimpleMinDimen keyword is found, the BodyMinDimen will instead be the smallest width or height found.

This was the default algorithm in releases prior to 3.1.6. The result

of the simple algorithm is less useful, as, for example for a

serpentine structure, it could be the line width, or the spacing.

There is yet another BodyMinDimen algorithm, associated with MOS

devices and indicated by the ContactMinDimen keyword. With this

keyword, and if a Permutes contact list is given, the BodyMinWidth will be the distance between the inside edges of the two

contacts in the Permutes list. This is the default for

recognized MOS devices, i.e., devices whose prefixes start with `m' or

`M', and overrides SimpleMinDimen if both are applicable.

For MOS devices, where it is assumed that the gate length (source to

drain) is constant, i.e., the gate is a strip that can meander

arbitrarily, even forming a loop, for device size measurements, one

can specify

length = BodyMinDimen

width = BodyArea/BodyMinDimen

The next four keywords have two optional trailing fields. The value

in each field must be a single digit. The digit corresponds to a Contact, in order of appearance in the device block, starting with 0.

If one or both fields is left off, the effective entry is 0. If both

contacts are given the same digit, the second one is incremented.

Thus, leaving off the trailing fields is equivalent to ".0.1". If the

indices don't point to an existing contact, or are not single digits,

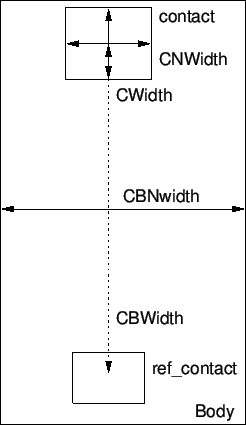

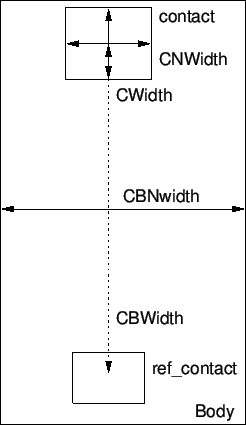

the measurement will fail. These are illustrated in Figure

16.1.

The ``body bounding box'' is the rectangular region encompassing

the Body objects, before any bloat.

- CWidth[.n1.n2]

The width of the first contact, along a line connecting the first

contact with the second contact.

- CNWidth[.n1.n2]

The width of the first contact, normal to the line connecting the

first contact to the second contact, measured at the contact

bounding box midpoint.

- CBWidth[.n1.n2]

The width between the first contact and the second contact, which

lies over the body bounding box.

- CBNWidth[.n1.n2]

The length of the line normal to the line between the first contact and

the second contact, over the body bounding box, passing through the

center of the body bounding box.

Example:

Contact s CAA CAA & !CPG

Contact d CAA CAA & !CPG

Contact g CPG CAA & CPG

Measure Length CBWidth.0.1 * 1e-6

Measure Width CBNWidth.0.1 * 1e-6

Note that the conversion to meters is included in the Measure

lines in the example above.

The following two keywords contain two trailing fields, which are

mandatory. The first field contains a contact index as above. The

second field contains the name of a layer.

- CArea.n1.lname

Construct a single polygon from the connected objects on the named

layer, one of which intersects the bounding box of the given contact.

The area of the polygon is returned. Note that the constructed

polygon can extend outside of the device's bounding box. If the

device being measured is merged, then the result is the sum of the

results from each component.

- CPerim.n1.lname

Measure the perimeter length of the polygon constructed as above. If

the device being measured is merged, then the result is the sum of the

results from each component.

When measuring with CArea/CPerim (for MOS ad/as/pd/ps), there is a

test to see whether the area intersects other device contacts from the

same device type. If a contact is shared between two devices, e.g.,

common active layer for two series-connected MOS devices, the

following algorithm is invoked.

For the shared contact:

- Compute the total contact area and perimeter for both devices.

- Compute the area and perimeter for the contact area common to

both devices.

- Subtract 1/2 this value from the parameters computed in the

first step.

This algorithm should work whether or not the devices are

multi-component and merging is enabled.

Example:

Contact s CAA CAA & !CPG

Contact d CAA CAA & !CPG

Contact g CPG CAA & CPG

Measure AS CArea.0.CAA

Measure AD CArea.1.CAA

Measure PS CPerim.0.CAA

Measure PD CPerim.1.CAA

- Resistance

Extract the resistance value (see below).

- Capacitance

Extract the capacitance value. The returned capacitance value is

given by the BodyArea times the capacitance per unit area, plus the

BodyPerim times the capacitance per unit length. The capacitance

values are specified in a Capacitance line in the layer block of

one of the layers defining the device body, i.e., the layers mentioned

in the Body line. If no body layer contains a Capacitance specification, or if both parameters are zero, an error

results.

- Inductance

Extract the inductance value (see below).

- Mutual_Inductance

Extract the mutual inductance value. This is not yet implemented.

The internal device definition structure contains a flag that if set

causes the device to be treated as a MOS transistor. There are a few

MOS-specific tests and operations found in the extraction system,

which are enabled by the flag. By default, the flag is set if the

device Prefix starts with `m' or `M'.

There are also flags that are set if the device is determined to be

n-type or p-type. Presently, we only set these for MOS devices. By

default, if the device name begins with `p' or `P', the device is

assumed to be p-type, otherwise it is taken as n-type.

- NotMOS

If given, the flag that indicates that the device is a MOS transistor

will not be set, as it would normally be if the Prefix starts

with `m' or `M'.

- MOS

If this keyword is given, the flag indicating that the device is a MOS

transistor will be set. This overrides NotMOS.

- NMOS

Flags will be set to indicate that the device is an n-type MOS

transistor.

- PMOS

Flags will be set to indicate that the device is a p-type MOS

transistor.

- Ntype

Flags will be set to indicate that the device is n-type. This is

meaningful only for MOS transistors at present.

- Ptype

Flags will be set to indicate that the device is p-type. This is

meaningful only for MOS transistors at present.

- SimpleMinDimen

When given, and the ContactMinDimen is not applied or not

applicable, the BodyMinDimen measurement will be the smallest

trapezoid width or height found in the decomposition of the body

shape. This was the default algorithm in releases prior to 3.1.6, but

a better algorithm is the new default.

- ContactMinDimen [y/n]

This keyword has a dual purpose: to impose a MOS-like BodyMinDimen computation on other device types, and to turn off the

use of this algorithm in MOS devices, which use this algorithm by

default.

Recognized MOS devices are devices that have the internal flag set as

mentioned above. The device must also have a Permutes list for

this algorithm to apply. Most MOS devices have permutable source and

drain contacts.

In recognized MOS devices with permutes, the default BodyMinDimen calculation is to set this to the distance between the

inside edges of the two contacts listed in the Permutes list.

Thus, the BodyMinDimen will always be the device length

(source/drain spacing) even if the source-drain spacing is larger than

the device width. The simple ``line width'' algorithm normally

applied for the BodyMinDimen would be ambiguous as to whether

the BodyMinDimen is the device length or width.

If ContactMinDimen n is given for a recognized MOS device, the

line width algorithm will be used. The ``n'' can actually be

one of many tokens that indicate negativity, such as ``no'',

``false'', ``off'', ``0'', etc., case insensitive,

but the token must appear.

For devices that are not recognized MOS devices, the line width BodyMinDimen algorithm is used by default. However, if ContactMinDimen y is given, and the device has a Permutes list,

the BodyMinDimen will be computed as for MOS devices. The

``y'' can actually be missing, or can be one of many possible

tokens that indicate truth, such as ``yes'', ``true'',

``on'', ``1'', etc., case insensitive.

- LVS measure_expr [spice_name]

This keyword instructs Xic to perform a parameter comparison as

part of LVS. The measure_expr is either one of the names used

for a Measure statement in the device block, or a single-quoted

expression involving constants and names from Measure

statements. The spice_name, if given, is the token used in

SPICE element lines to designate the parameter, e.g., ``l'', ``w'',

``area''. This can be blank if comparing to an element value which is

given as a leading number, i.e., resistance, capacitance, etc. The

LVS directives must appear after the referenced Measure

line.

Examples:

Measure Area BodyArea*1e-12

LVS Area area

Measure Resistance Resistance

LVS Resistance

Any number of LVS lines can appear in a device block.

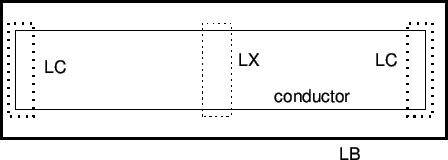

Figure 16.1:

The distances returned by the various width

measurement keywords to the device block Measure line.

|

- Spice specification_args

The Spice keyword specifies the format for the SPICE output part

of the listing from the Dump Phys Netlist command in the Extract Menu. The specification is copied verbatim, except for the

following substitutions:

-

\

n

The character sequence `

\

n' is replaced by a newline in the

expanded text. Note that the next token should probably begin with

the SPICE continuation character `+' for the SPICE output to be

interpreted correctly.

-

\

t

The character sequence `

\

t' is replaced by a tab character.

- %c%cname

The cname is a contact name (from a Contact line). This

token is replaced with the group number of the contact.

- %m[g | s[N] | f[N] |

e[N]]%mname

The mname is a name from a Measure line. The

token is replaced with the result of that measurement.

One of the characters s, g, f, e can follow the `m'. The s, f, e

can be followed by an optional digit. These select the format of

the printed result.

- g

Use the ``best'' numeric format (the default if no modifier given).

- sN

Use SPICE abbreviations, with N decimal places.

- fN

Use fixed point notation, with N decimal places.

- eN

Use exponential notation, with N decimal places.

If N is not given, the default is 5 digits.

Above, cname and mname can be followed directly by

`%' and other text, for a concatenation function. For example

``L=%m%Length%u'' might be replaced with ``L=.8u''.

- %n%

This token is replaced with a name for the device, which consists of

the Prefix (if given) followed by an index count for the device

type.

- %p lname pnum%

This token is replaced by the text of a physical property. The lname is the name of a layer, and space after the `p' is optional.

The pnum is a non-negative integer. Each of the objects on lname that intersect the device bounding box is checked for a

property with number pnum. The string of the first such

property found is used. This enables property text to appear in

device output, in particular it provides a means to coerce a value or

other parameter.

- %e%

If the electrical dual of the physical device is known, the %e% is replaced by the name of the electrical device. If no dual

is known, the behavior is the same as %n%.

- %f%

The substitution %f% is equivalent to %e% except that

if the dual device is unknown, the token is simply ignored.

Each of the substitution tokens can take an optional integer after the

first %, which indicates that the token refers to the device in the

n'th Find line (0 is the same as no integer).

Example:

Device

Name mut

Prefix K

...

Find ind

Find ind

Spice %n% %1n% %2n% ...

The Spice line prints the name of the mut device, followed by

the names of the two inductors.

- %model%

Replaced by contents of the Model line (see below).

- %value%

Replaced by contents of the Value line (see below).

- %param% or %initc%

Replaced by contents of the Param line (see below).

The Spice line is used in Dump Phys Netlist output and

internally by Source Physical command.

- Cmput specification_args

This specifies the format used in printing the device parameters from

the Show computed parameters of selected device option of the

Enable Select command mode in the Show/Select Devices

panel The substitutions are exactly as those of the Spice

keyword. For example:

Device

Name res

...

Measure Resistance Resistance

Cmput Resistance = %m%Resistance ohms

End

These keywords specify a format string to use when creating ``property

strings'' from the extracted parameters of a physical device, to be

used for comparison or updating the properties of the corresponding

electrical device. These are used in the Source Physical

command, and in the Show elec/phys comparison of selected

devices option of the Enable Select mode in the Show/Select Devices panel. This panel is brought up by the Device Selections button in the Extract Menu.

The format is the same as is described for the Spice line,

however the escapes %model%, %value%, and %param% are not recognized.

The Model, Value, and Param lines are used

internally when comparing physical devices to their electrical

counterparts. This is done, for example, in the Show elec/phys

comparison of selected devices option of the Enable Select mode

in the Show/Select Devices panel. This panel is brought up by

the Device Selections button in the Extract Menu.

The Set varname = something construct in the

technology file can apply to lines in device blocks, however the

Set keyword must appear outside and before the block. Device

block lines can contain $(varname) tokens, which

are replaced with something before the line is parsed.

The format specifications for the Spice, Cmput, etc.

lines can contain the eval(...) construct. The argument to eval is evaluated as a mathematical expression, and the result

replaces the entire construct. Unlike elsewhere in the technology

file, in these lines this construct is evaluated when the line is

used, and not when the technology file is read.

The extraction mechanism can be tested with the !find command,

or with the device listing capability in the Show/Select Devices

panel from the Device Selections button in the Extract

Menu.

Xic contains functionality for accurately calculating resistor

values of arbitrarily shaped resistors. Resistance extraction is

accomplished by dividing the resistor logically into a regular grid.

The center of each grid is a ``node'' that is connected by resistance

to adjacent nodes. Thus, the problem becomes one of solving a large

lumped resistor mesh.

Best accuracy is obtained when the grid falls on all the resistor and

contact boundaries. It is not possible to find such a grid in

general, however if a layout grid is used and all corners are on-grid,

and all edges are Manhattan, then tiling will be possible. It may be

the case that tiling is possible, but the tile is so small that the

computation time is unacceptable.

For structures that can't be tiled efficiently, a set of

edge-dependent heuristics is used to modify the matrix elements to

account for the local area deficit or surplus.

There are four variables that can be used to configure the extractor.

The default values lean toward speed over accuracy. By default,

tiling is not attempted, and the grid spacing will be selected so that

each resistor contains 1000 grid cells.

-

- RLSolverDelta

Value: floating point > =

0.01.

It this value is set, the resistance/inductance extractor will assume

this grid spacing, in microns. The number of grid cells enclosed in

the device will increase for physically larger devices, so that larger

devices will take longer to extract. If this variable is set, the

other RLSolver variables are ignored. Setting this variable may

be appropriate if all resistors are ``small'' and dimensions conform

to a layout grid.

- RLSolverTryTile

Value: boolean.

If set, the extractor will attempt to use a grid that will fall on

every edge of the device body and contacts. The device and contact

areas must be Manhattan for this to work. If such a grid can be

found, and the number of grid cells is a reasonable number, this will

give the most accurate result.

- RLSolverGridPoints

Value: integer 10-100000.

When not tiling (RLSolverTryTile is not set), this sets the

number of grid points used for resistance/inductance extraction. This

number will be the same for all device structures, so that computation

time per device is nearly constant. Higher numbers give better

accuracy but take longer. The value used if not set is 1000.

- RLSolverMaxPoints

Value: integer 1000-100000.

When tiling (RLSolverTryTile is set), the maximum number of grid

cells is limited to this value. If the tile is too small, it will be

increased in size to keep the count below this value, in which case

the tiling will not have succeeded so there may be a small loss of

accuracy. Using a large number of grid points can take a long time.

The value used if not set is 50,000.

The resistor solver is accessed through the device block Measure

keyword ``Resistance'', for example:

Device

Name res

...

Measure value Resistance

End

By including the ``Measure value Resistance'', all resistances

may be extracted and the values will appear in the output of the Dump Phys Netlist command. When computing the resistance, the layers

in the Body specification are checked for an Rsh

specification, or alternatively a Rho or Sigma

specification along with a Thickness specification. If the

resistance parameters are not found, an error results. Unlike

releases prior to 3.1.6, there is no default resistance.

Xic also contains functionality to measure conductor inductance

values. Inductance is extracted using an algorithm similar to

resistance, i.e., square counting, but other factors are included to

enhance accuracy. This assumes ``microstripline'' geometry, meaning a

conductor separated from a ground plane by a uniform dielectric. The

Measure keyword is ``Inductance''. The inductance per

square is derived from the microstrip parameters for the layer, as

provided with the Tline specification. A Tline

specification must be given to one of the device body layers, or an

error results.

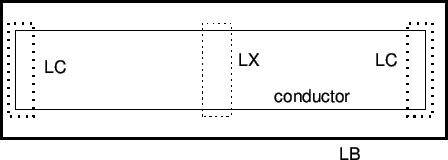

Presently, the recommended way to set up inductors for extraction is

through the use of three additional layers. These layers can have any

name but will have the following names in this discussion:

- LB

Used to outline the inductor, will surround the region of a

conductor where inductance is to be measured.

- LC

Identifies the inductor contacts (inside LB and on the

conductor).

- LX

Bisects the conductor into two areas to provide separate groups for

the two contacts.

Figure 16.2:

Illustration of the configuration of layers

LB, LC, and LX for extracting inductance from a conducting strip.

The LX ensures terminal assignments to different groups.

|

These layers have been added to the xic_tech.hyp file provided.

The ``Exclude LX'' clause must be added to the Conductor

specification of the conductors to be extracted.

Next: Device Templates

Up: Extraction System: Setup and

Previous: Extraction System: Setup and

Contents

Index

Stephen R. Whiteley

2025-02-09